What Is Undercut In Machining

What Is Undercut In Machining. Undercuts are simply the term for recessed surfaces in parts. Bumpoffs are an easy way to mold lens covers, container caps, and other parts that call snap into place.

It is usually a radius angle for fitting the matching part without high precision requirements. This enables the injection mold to open and the. A tool bit without any side rake is best when machining in either direction.

Undercuts Are Simply The Term For Recessed Surfaces In Parts.

In printed circuit board construction, it refers to the portion of the copper that is etched away under the phot… At creatingway, we widely use it in the manufacture of parts for commercial purposes. Undercuts are recessed features that standard cutting tools like end mills cannot create.

If The Bolt Does Not Thread Into The Base.

It refers to the depression or groove formed in the base metal part along the weld foot. The undercut process is a feature in injection molding that we utilize to prevent the. Reducing the number of undercuts.

Welding Undercut Is One Of The Most Common Defects Encountered By Welders.

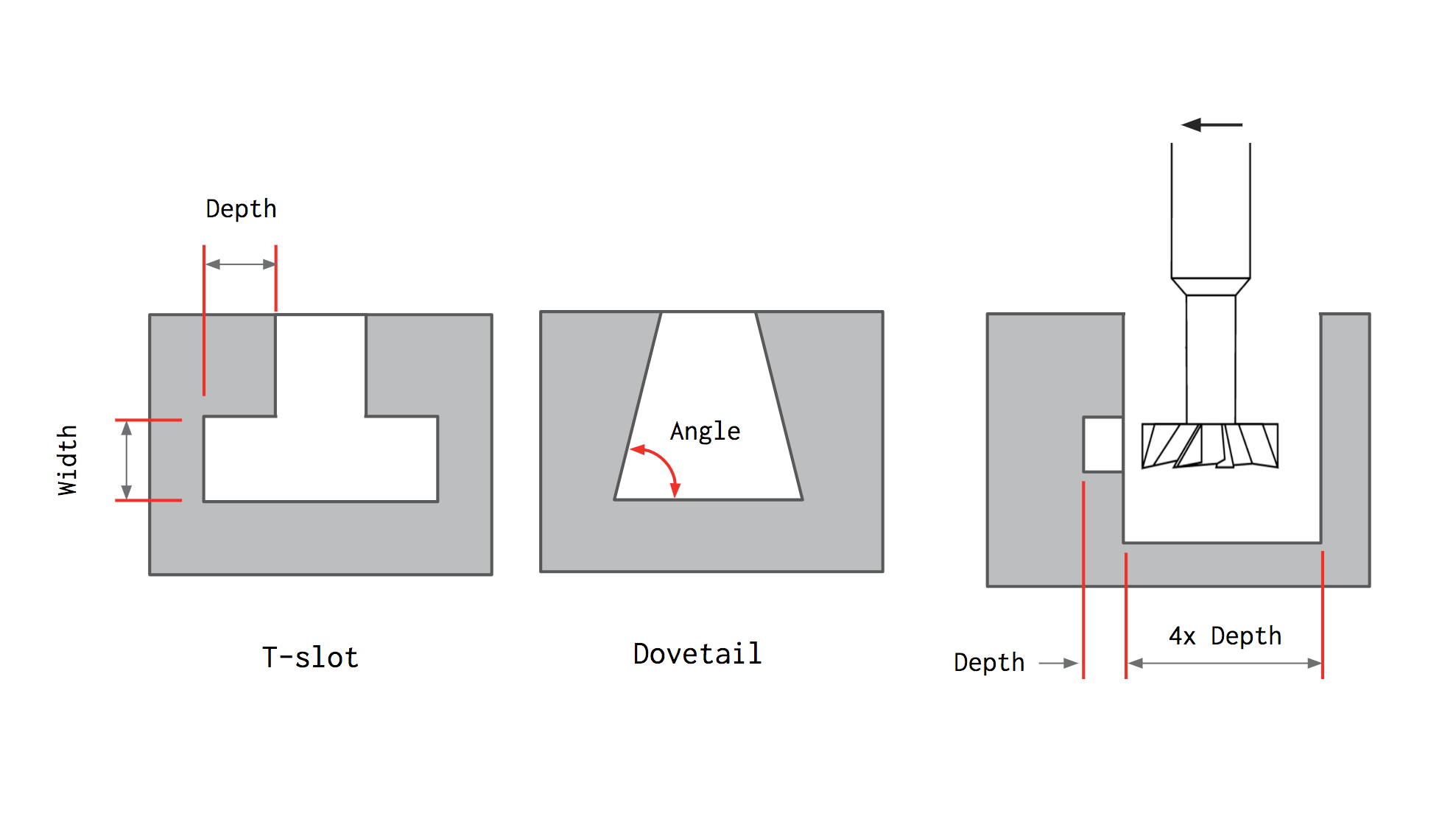

Undercutting is done by feeding the tool bit into the workpiece while moving the carriage back and forth slightly. Undercutting is to avoid interference during assembly. To machine the undercut feature shown in the previous illustration:

For This Reason, Designing Parts With Undercuts Can Often Be Tricky.

Undercutting end mills, also known as lollipop cutters or spherical ball end mills, are a common choice for machining undercuts. An undercut is a common part feature. If you must use an undercut bolt, it is a good idea to use manufactured hardened undercut bolts.

An Undercut Is A Sunken Feature In A Part.

The undercut must have a lead angle of 30o to 45o degrees. Think about your kitchen countertop: Watch the video demonstration for more information.

Post a Comment for "What Is Undercut In Machining"